Wednesday, October 31, 2012

Iron Profile: Caterpillar 777 Off-Highway Haul Truck

Introduced by Caterpillar in 1974, the 777 became one of the company’s most popular line of off-highway haul trucks. Building on their experience with the 769B and 773 trucks, the 777 continued the successful mechanical-drive haulers into the 85 ton class. This truck featured the 870-flywheel-horsepower D348, V-12 diesel engine, and low weight-to-horsepower ratio. With the seven-speed planetary transmission, this power was put to good use, typically in mining and large earthmoving projects.

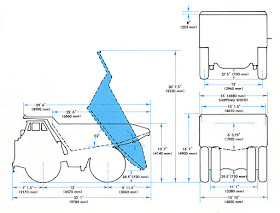

The 777 had a newly designed front end, ROPS cab and engine deck. This allowed much easier in-frame servicing by technicians, and was so successful it continues to be the basic design used today. The ride over rough quarry roads was made smooth by four huge oil-pneumatic suspension cylinders. The two front cylinders acted as steering kingpins for a short turning radius in tight loading spots. The 777 could make a clearance turning circle in 88 feet.

The Cat 777 body had the same familiar features that proved so reliable and durable on the 769B and 773 trucks: dual-sloped dump bed designed for retaining heaped loads up steep inclines, wrap-around ribs for added strength, steel corner castings and rolled steel toprail sections to reinforce critical stress areas, and a low loading height. The ten box-sectioned ribs also had the unique feature of funneling engine exhaust to heat the bed for easier dumping of sticky materials in cold weather.

So successful was this haul truck it found itself developed by Caterpillar into an off-highway tractor called the 776. This powerful tractor proved versatile enough to become popular in variations modified to suit a wide spectrum of needs. High-capacity dump bodies, coal haulers, and heavy equipment trailers—all have seen use.

The 777 series truck has continued over the years to its current version, the 777G, with new advances in technology refining its weight class. For almost three decades this hauler has proven itself one of Caterpillar’s most durable and successful trucks.

SPECIFICATIONS:

Horsepower, flywheel — 870 (649 kW)

Total empty weight —122,600 lb. (55,610 kg)

Loaded weight to Hp ratio (with standard options) — 336:1

Capacity, tons — 85 (77t)

Cubic yards, struck (SAE) — 47.5 (36 m3)

Cubic yards, heaped 2:1 (SAE) — 67.1 (51 m3)

Transmission — 7 range automatic power shift with 1 reverse range.

Top speed loaded — 33 MPH (53 km/h)

Friday, October 26, 2012

CCM Behind the Scenes: Designing the 3D Model

Once we’ve collected all the research materials that we'll use to develop our next model of a construction machine—including diagrams, photos, manufacturer’s CAD files, and our model survey measurements—our product designers begin work on the 3D model. This is a computer-rendered, three dimensional file that will be used by our manufacturers to produce the tooling necessary for casting the production models.

Depending on the complexity of the machine, the design of the 3D model can take a month or more. A company such as Caterpillar will usually have CAD plans of their current equipment that we can use as a base. These are often incredibly complex, containing plans for wiring, hydraulics and every last bolt. We carefully strip away everything until we have just the amount of detail that will survive the transition to a 1:24, 1:48 or 1:87 scale model.

If it’s a vintage machine, such as our Cat 992C, the 3D model is painstakingly developed from scratch. This is where our survey comes in really handy. What does the bottom of that transfer case look like? Good thing we like to get under the real equipment to find out!

During this process we also determine important things like how the doors will hinge, tracks and booms will function, and even where we’ll hide the screws. We design in a program called SolidWorks, which helps our product developers to simulate materials, fasteners, and moving parts—all before we send the plans out for tooling to be made.

When our 3D model is finished we’ll all review it along with the equipment engineers for inconsistencies with the real machine. We’ll also have historians expert in construction equipment take a look to see if there might be something we overlooked. It's all in the details, after all.

A physical mockup of the scale model might be done at this point on our rapid-prototyping 3D printer in resin. This allows for function testing and more fine adjustments to be made to the parts before we send the plans to the manufacturer.

Next, we await the tooling sample.

Wednesday, October 10, 2012

Cat 5230 model in production, both versions

Here's a few more photos of our upcoming 5230 in production. It's looking great even without paint. For the first time you can also get a comparison of the Front Shovel alongside the Mass Excavator version. Enjoy!

Monday, October 8, 2012

Cat 5230 model in production

We thought you might enjoy an update on our 5230 1:87 scale brass model. These photos show some of the sub-assemblies in production.